Main Feature

- The modular design realizes different functional configurations according to customer requirements, each module driven by independent servo motor, to ensure machines at stable, convenient, accurate, efficient and other performance.

- Excusive design for heavy duty corrugated board, perfect creasing performance to avoid fish tail and guarantee the glue gap accuracy.

- Equipped with high-precision linear guide rail and electric moving plates device.

Technical parameter

|

Model |

HL-2000AC-A |

HL-2400AC-A |

HL-2800AC-A |

|

Applicable material |

250~800g/m2 ( cardboard ), N, G, F, E, C, B flute 3ply corrugated board, and 5ply corrugated board. |

||

|

Speed range |

0~200m/min |

0~200m/min |

0~200m/min |

|

Inching speed |

30m/min |

30m/min |

30m/min |

|

Max blank width |

2000mm |

2400mm |

2800mm |

|

Dimension(L*W*H) |

22000*2900*1860mm |

22000*3300*1860mm |

22000*3700*1860mm |

|

Mechanical weight |

15.5T |

16.5T |

17.5T |

|

Mechanical power |

56KW |

56KW |

61KW |

|

Max thickness of folded box |

15mm |

15mm |

15mm |

|

Compressed air |

6 bar |

6 bar |

6 bar |

|

Air compressor capacity |

10 m3/h |

10 m3/h |

10 m3/h |

|

Air tank capacity |

60L |

60L |

60L |

Feeder Unit

- Independent motor drive.

- Adjustable vibration motor.

- The side baffle is equipped with motor toadjust the width.

- Three sets of adjustable feeder knives.

- Adopt high performance suction belts torealize the stability of paper feeding.

Creasing Unit

- Exclusive secondary creasing function device.

- Equipped with four sets of main drive creasing wheels.

- The cylinder regulates the pressure of thelines creasing wheels.

- Can effectively improve the bellmouth and tolerance of final-folding boxes.

Final-folding Unit

- Upper and lower belt double drive maintransmission system, to ensure smooth delivery of three and five layer cartons.

- Left and right inflection belts by independentservo drive, the end of final-folding is equip-pedwith independent belts extrusion function.

Output Unit

- Servo motor independent drive.

- Electric adjustment length of upper andlower bracket telescopic rod.

- Equipped with automatic belt tension adjustment system.

Conveyor Unit

- Upper and lower both independent servo motor drive.

- Upper conveyor equipped with independent motor for the forward and backward moving adjustment according to different box.

- Equipped with pneumatic pressure control system, easy to adjust, can effectively ensure the uniform pressure.

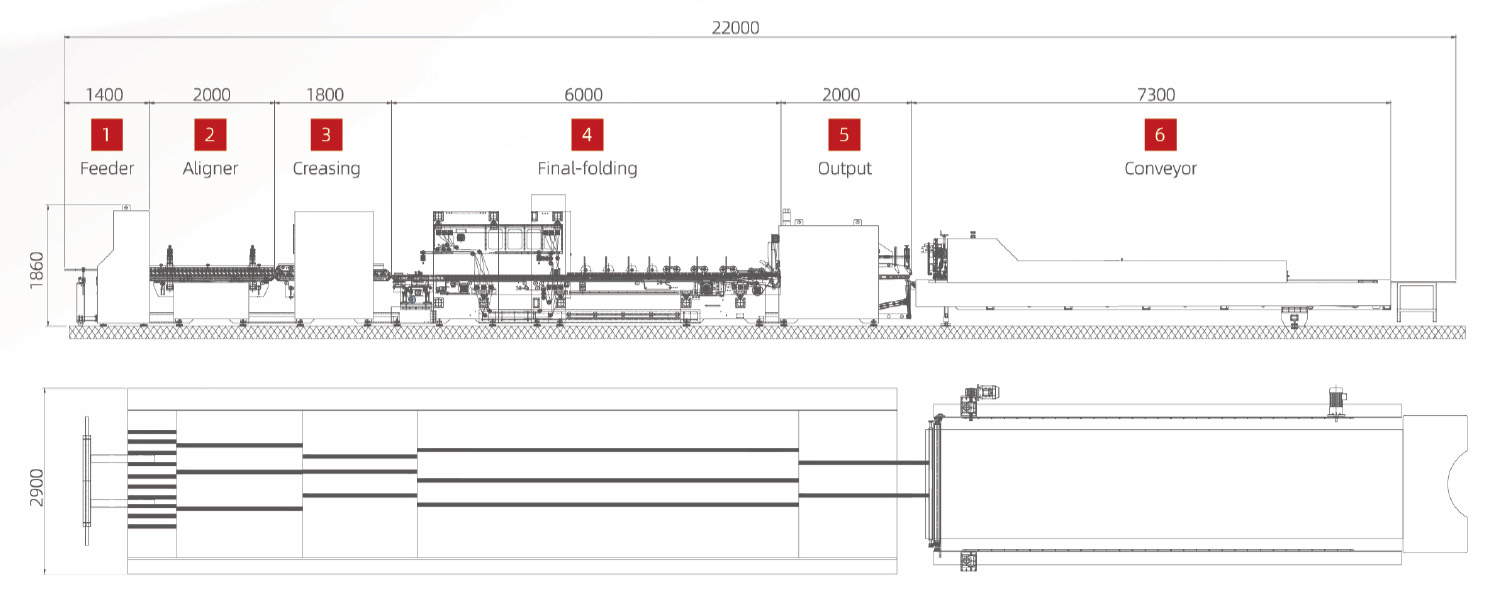

Layout